“Any customer can have a car painted any color that he wants, so long as it is black.”

– Henry Ford, speaking about the Model T

Thankfully, that era is over.

When Speed UTV entered the market, it wasn’t just to build another side-by-side — it was to rethink what the custom off-road experience could look like. As the creative lead for the Speed UTV graphics program, I helped turn the idea of mass customization into reality, one machine at a time.

The Challenge: Customization at Scale

With over 5,000 Speed UTVs sold, the brand promised more than just performance — it promised personalized design. My job was to make that happen.

Each UTV customer was offered four distinct livery design options per model — Bandit, El Jefe, and Diablo — with full-color customization across multiple layers. Unlike most OEMs offering a single paint scheme or limited wraps, Speed UTV let owners choose from 45+ colors, gradients, and finishes, creating millions of unique combinations.

Every custom design received a unique master number, tying the visual configuration to a specific VIN for production accuracy.

My Role: From Illustrator Templates to Production-Ready Wraps

I led the visual execution of the entire livery customization process. Here’s how:

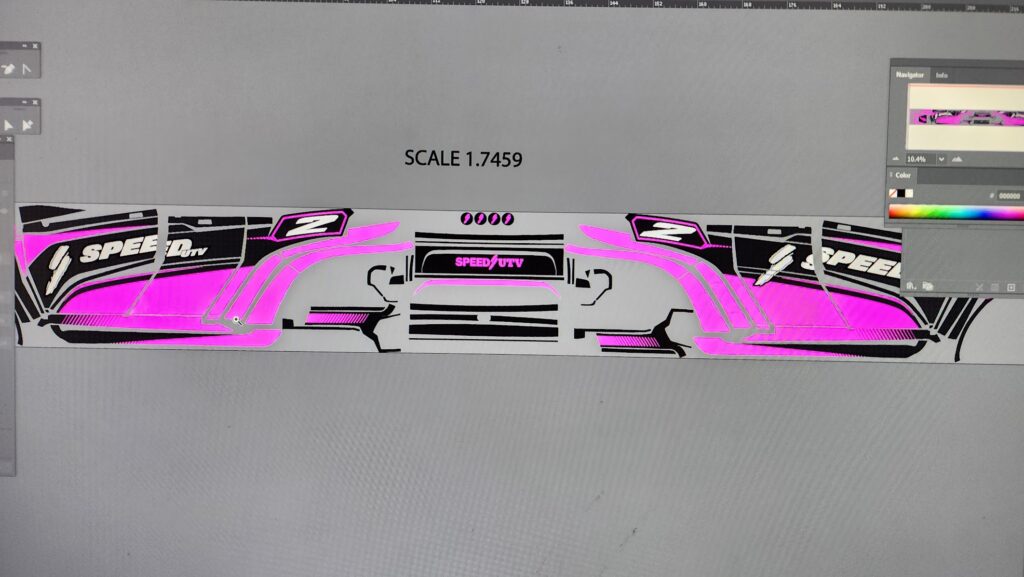

✅ Created Model-Specific Illustrator Templates

Using SolidWorks DXF files exported from the CAD engineering team, I built precise vector templates in Adobe Illustrator for all three Speed UTV models. These templates had to align with panel curves, bolt holes, and aerodynamic elements.

Each model — Bandit (2-seat), El Jefe (4-seat), and Diablo (wide track) — featured four high-impact design choices, pre-separated into customizable layers.

✅ Designed for Flexibility

I developed a modular design system that allowed each customer to toggle through color combinations and logo placements via an interactive online builder. This gave customers creative freedom without overwhelming the production backend.

✅ Production Pipeline Coordination

To ensure consistent print results, I converted HEX color codes into Pantone values, maintaining uniformity between what customers saw online and what got printed overseas. The wraps were then applied directly to panels before final vehicle assembly — requiring extreme precision to match curves and corners.

✅ Master Database Management

Each livery configuration was cataloged with a unique master wrap number, making the entire process traceable and repeatable. This also allowed for reprints or warranty replacements without starting from scratch.

Results

- 5,000+ units with custom graphics shipped globally

- 12 Illustrator wrap templates built (4 designs x 3 models)

- Millions of possible combinations handled through a streamlined system

- Customer satisfaction scores soared thanks to OEM-level personalization

Why It Mattered

Customization at this scale is rare in the powersports industry. Most manufacturers limit options to streamline production. But Speed UTV flipped the script, and I helped build the visual language and backend system to make it real.

This wasn’t just graphic design — it was design engineering, product personalization, and user experience design rolled into one.